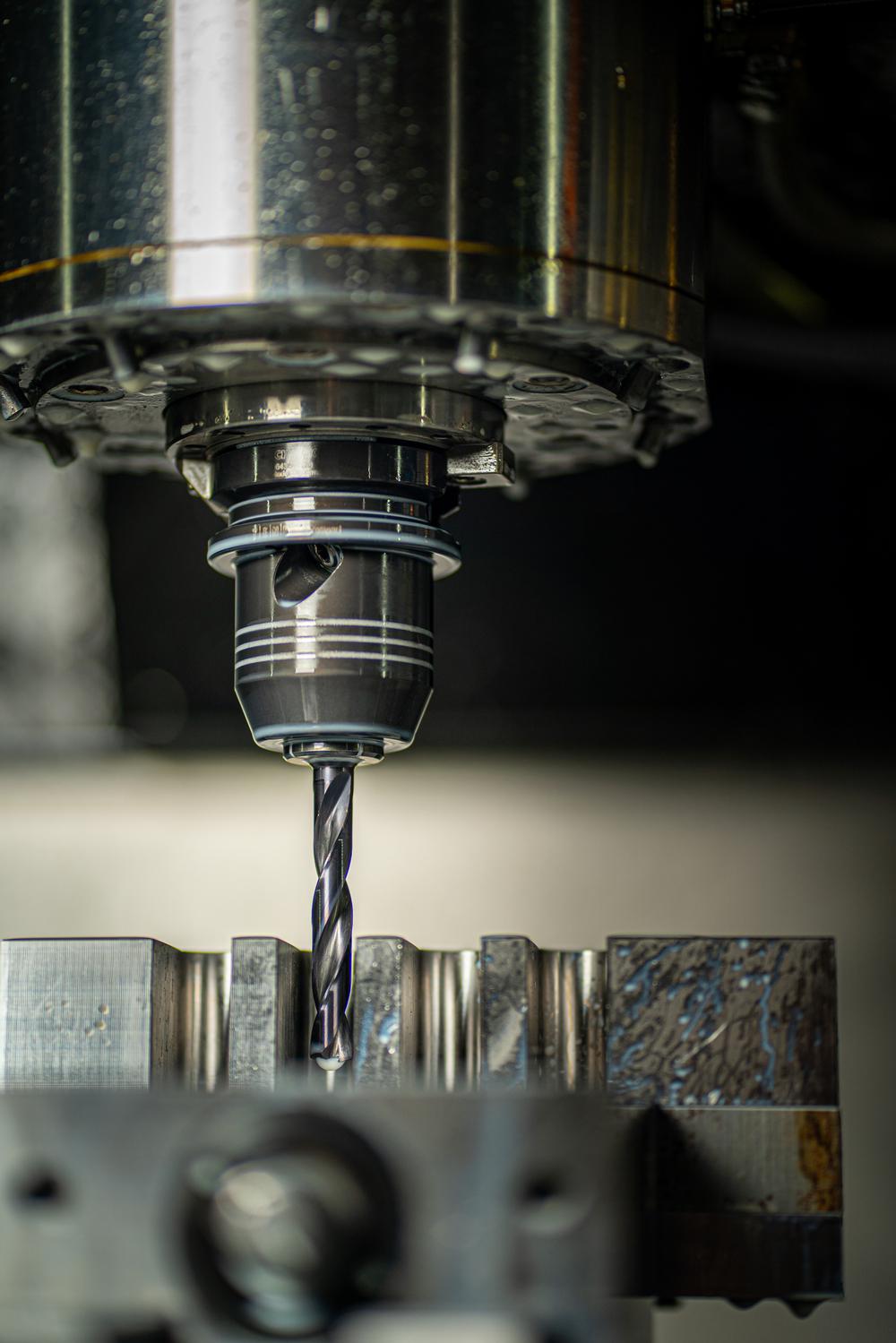

A CNC milling machine was used in this dataset to carve S an shape into a wax part.

Different experimental configurations were used, most notably variations in tools conditions (worn/unworn), feed rate and clamping pressure.

At the end, the operator notes if she was able to complete the operations and if the appearance of the part is satisfactory.

Therefore, we are able to make three predictions

- is the pressure enough to finish machining?

- given the state of the final product, is the tool worn out and should we change it?

- given the state of the tool and the operating conditions, will the finish product pass visual inspection?

Here we focused on predicting if the tool is worn or not.

So 87% percent of the time, we are able to tell if the tool is worn out or if we can continue using it.

That way, instead of the traditional approach consisting of changing a tool on a fix schedule, you can use AI to only change it when it's actually necessary. Saving on tools, maintenance and manpower.