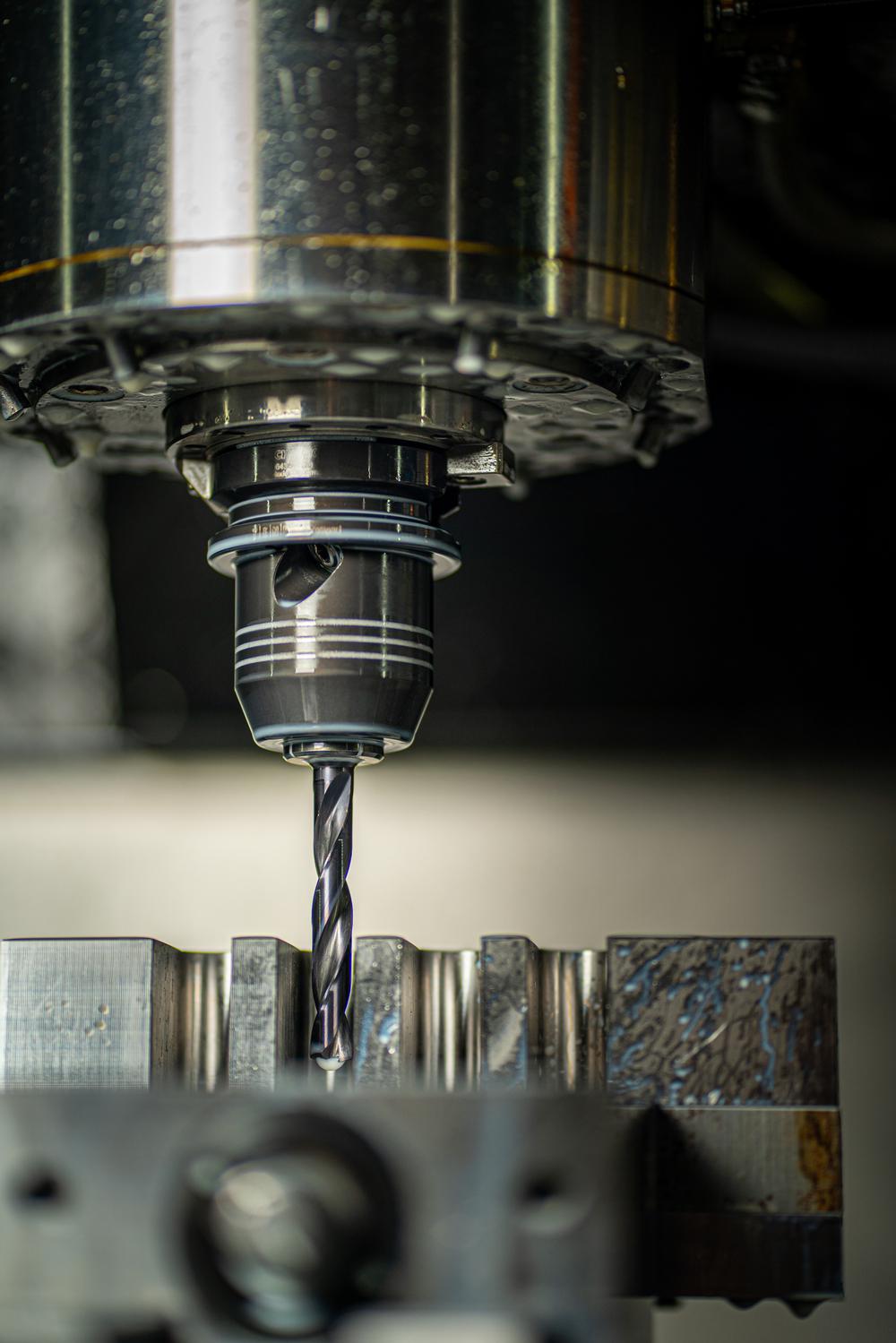

A CNC milling machine was used in this dataset to carve S an shape into a wax part.

Different experimental configurations were used, most notably variations in tools conditions (worn/unworn), feed rate and clamping pressure.

At the end, the operator notes if she was able to complete the operations and if the appearance of the part is satisfactory.

Therefore, we are able to make three predictions

- is the pressure enough to finish machining?

- given the state of the final product, is the tool worn out and should we change it?

- given the state of the tool and the operating conditions, will the finish product pass visual inspection?

Here we focused on predicting if we will pass visual inspection and achieve great results with 98% accuracy.

So 98% percent of the time, we would be able to tell if the product will be satisfactory ahead of time and therefore reducing costs and wastes.